Waste Heat Drives the Use Cases

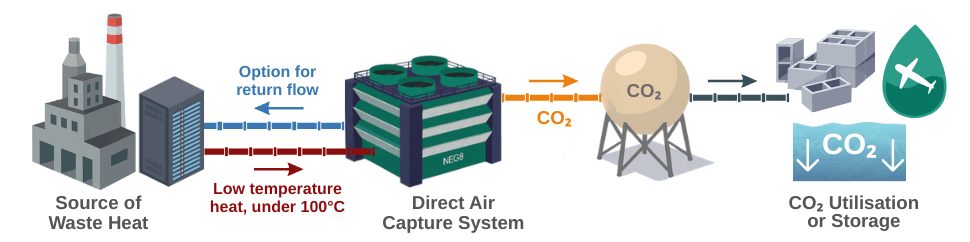

NEG8 Carbon’s technology requires an extremely low regeneration temperature of 65°C. This low temperature allows NEG8 to co-locate with industrial processes to use their low grade waste heat as heat input into the Direct Air Capture (DAC) units thereby greatly reducing the energy consumption of DAC.

In the case of NEG8 Carbon, the energy consumption of the DAC units is 71% less when using waste heat compared to not using it.

This creates opportunities for versatile adoption of DAC technology across multiple industries.

Use Cases Where DAC can Avail of Waste Heat

e-SAF/e-Fuel Production

Use Fischer Tropsch process heat to power low cost CO₂ production with DAC.

This slashes the cost and boosts the efficiency of Sustainable Aviation Fuel (SAF) and e-fuel manufacture, which is integral to decarbonising the transport sector. This approach supports the aviation industry’s drive towards lower emissions and cleaner fuels.

Cement Plants

Valorise cement plants’ process heat to produce green CO₂ with multiple use cases.

Cement plants emit mixed CO₂, which is difficult to use in most carbon utilization technologies. However, NEG8’s DAC technology provides high purity CO₂ thus enabling cement plants to access new commercial avenues and contribute to decarbonisation.

For more:

Storing CO2 in Concrete for Sustainable Construction

Data Centres

Turn the waste heat from essential data centre cooling systems into net-zero gains using DAC.

Rather than letting this energy go unused, DAC systems can tap into the heat produced by data centres to capture CO₂ from the air. In Ireland alone, the waste heat from data centres could support the capture of approximately 500,000 tonnes of CO₂ per year.

For more:

Direct Air Capture and Data Centres Working Together

Electrolysers

Use the electrolysers’ cooling water, at temperatures as low as 65°C, to capture CO₂ with DAC and produce high purity feedstock for e-fuel.

By placing DAC units alongside electrolysers, both hydrogen and CO₂ can be produced on-site. This co-location approach provides all the essential inputs needed for synthesising e-fuels, while making productive use of available energy.

Uses for CO₂ Captured Using DAC

The DAC-captured CO₂ can be permanently stored (What is Carbon Sequestration?) and sold as carbon credits/offsets, or used in various applications. (What is CO₂ Utilization?)

For more: