Storing CO₂ in Depleted Oil & Gas Reservoirs

8 September 2025

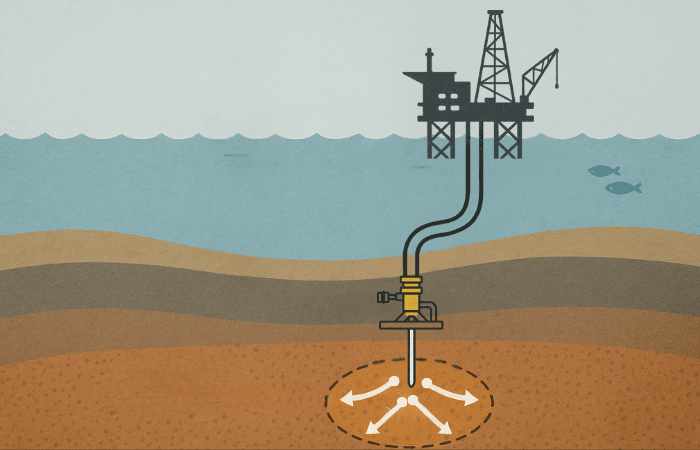

Decommissioning a depleted oil or gas reservoir is an expensive task. But what if these same wells, instead of being a liability, could generate revenue again? But this time by locking away carbon dioxide for climate change mitigation.

Is it Feasible to Repurpose Depleted Oil and Gas Wells to Store CO₂?

Depleted oil/gas reservoirs often have exactly what storage needs: proven traps, well-mapped geology, and decades of pressure/flow data. They are strong candidates with good sealing formations and sizeable capacity. Moreover, projections suggest that over 20,000 offshore wells will require decommissioning in the coming 10 to 15 years. (World Oil)

As a case in point, the INEOS-led Project Greensand in Denmark is set to start CO₂ storage operations into the depleted Nini West oil field in the North Sea at the end of 2025/early 2026, scaling from a successful 2023 pilot to full commercial phases this decade.

Initially, the reservoir will store 400,000 tonnes per annum of CO₂ expanding to 8 million tonnes per annum towards 2030. The captured, liquefied CO₂ will be shipped to the Nini field for permanent storage 1,800m subsurface.

Other projects:

Heidelberg Materials is behind the carbon capture facility at Padeswood cement works in North Wales. The project is due to come online in late 2025 and aims to capture 800,000 tonnes of CO₂ per annum. The captured CO₂ will be transported via the HyNet North West pipeline and stored permanently in depleted gas reservoirs located deep beneath the seabed in Liverpool Bay. (Hynethub | Carbon Herald)

The Peak Cluster project is another UK carbon capture project in development. It covers the Tunstead Quarry in Buxton where cement and lime are produced, and cement plants in Derbyshire and Staffordshire. The CO₂ will be piped to a former gas reservoir under the Irish Sea off the coast of Morecambe in Lancashire for storage, and once operational, the project aims to prevent three million tonnes of CO₂ entering the atmosphere every year. (BBC)

Deepwater Oil and Gas Technology Transfer

Meanwhile, in the Netherlands, a successful pilot project has been completed using proven deepwater oil and gas technology to securely store CO₂ in a mature offshore well. By using available technology, the oil well was secured with instant integrity. (World Oil)

What is Needed to Repurpose Oil/Gas Wells?

Basically, you need to check for any possible risks: consider site characterisation, cap rock stability, faults, etc. Furthermore, legacy wells must hold up to integrity tests, and pipelines likewise have to be inspected.

Another important aspect is CO₂ quality and compression, where water and impurity levels are controlled to reduce corrosion and avoid hydrate risks. Alongside this, monitoring, reporting, and verification (MRV) is carried out in line with permit requirements and regional rules.

But in the end, re-use is attractive as it saves cost and time, though it is not always possible.

Benefits and Challenges of Storing CO₂ in Decommissioned Oil/Gas Reservoirs

Benefits

Using existing, unused wells and infrastructure provides a cost-effective path to large-scale CO₂ storage. This option taps into the vast technical knowledge and expertise of oil/gas engineers and technicians that can be re-focused to decarbonising fossil fuels.

Since the geology is already well understood and backed by years of data, you can characterise sites faster and with greater confidence than unproven formations. If re-use passes integrity checks, capital expenditure can fall, and timelines shorten. In addition, UK and EU policy support and funding are creating strong demand for storage.

Challenges

To begin with, legacy well risk remains a concern, as old wellbores can leak unless they’re remediated, which often means integrity repairs. In addition, re-use has limits because some pipelines and platforms fail CO₂ suitability tests, so savings aren’t guaranteed. Furthermore, subsurface controls are important and careful modelling and tight operating envelopes help prevent fault reactivation or induced seismicity.

For more: What is Carbon Sequestration?

Monetising a Depleted Oil/Gas Well: The Business Case

By repurposing oil/gas reservoirs for CO₂ storage, you turn decommissioning costs into an asset and create new revenue streams. Besides the cost benefits, this process contributes to the drive to net-zero and achieving climate targets.

Furthermore, storage is monetised through transport and storage tariffs, with industrial emitters paying per tonne for both injection and MRV.

As compliance markets expand, this predictable demand underpins long-term contracts. Additionally, both the UK and EU are moving to integrate carbon dioxide removals into their Emissions Trading Systems (ETS), which will strengthen the case for carbon capture and storage. Beyond ETS, permanently stored CO₂ can be traded and sold as carbon credits or voluntary offsets.

Finally, regional storage hubs create powerful cluster effects by anchoring pipelines, shipping, and service networks, which improves utilisation rates and drives down per-tonne costs.

Turning our attention to the capturing of CO₂:

Using Low Grade Waste Heat from CO₂ Compressors to Power Direct Air Capture

When CO₂ is compressed after capture the process generates a considerable amount of low-grade waste heat. Normally this heat is lost to the environment, but it can be recovered and used as a useful energy input for Direct Air Capture (DAC) systems that operate below 100 °C.

Most DAC processes rely on either liquid solvents or solid sorbents to trap CO₂ from the air. To release the CO₂ again, the sorbent must be regenerated, which usually requires heating. If the regeneration step operates at under 100 °C (such as NEG8 Carbon’s DAC technology), the waste heat from the compression stage can be diverted into this part of the process. In practical terms, this means the system uses “free” energy that would otherwise be discarded, instead of drawing as much from external electricity or fuel.

By integrating the compression and capture steps in this way, the overall energy demand of the DAC unit is reduced. This has two direct benefits:

- Lower operating costs: less purchased energy is needed.

- Improved affordability and scalability: making DAC more competitive against other carbon-removal approaches.

This makes DAC particularly well-suited to coupling with CO₂ compression heat recovery.

For more: Direct Air Capture + Waste Heat Use Cases

The Bottom Line

Storing DAC CO₂ in depleted oil and gas fields is technically feasible and already moving from pilots to commercial projects. The prize is twofold: dependable storage for negative emissions and a way to earn from assets otherwise headed for decommissioning.

For more:

- Storing CO2 in Concrete for Sustainable Construction

- Direct Air Capture and Data Centres Working Together