Solid Sorbent DAC Compared with Electrochemical DAC

25 October 2025

By Prof. Don MacElroy (Professor Emeritus in Chemical Engineering, University College Dublin, and Chairman of the NEG8 Carbon Advisory Board) and Jeannie De Vynck

Solid sorbent Direct Air Capture (DAC) and electrochemical DAC are two leading technologies for removing carbon dioxide (CO2) from ambient air. Both approaches have distinct processes, energy needs, and opportunities to reduce costs.

How the Technologies Work

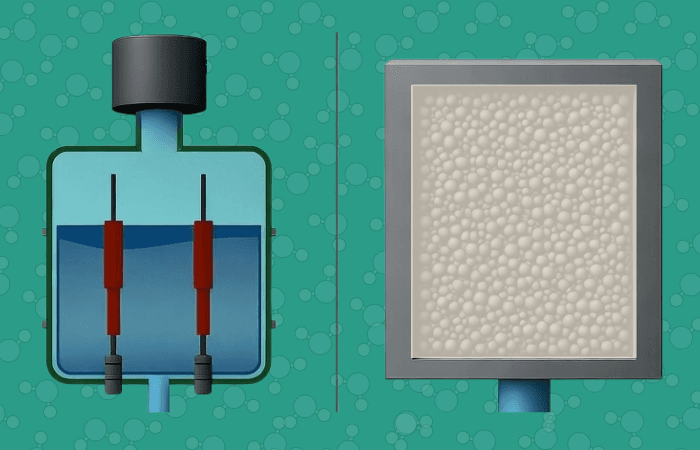

Solid sorbent DAC draws air over solid sorbents (often amino-functionalised solid supports or metal-organic frameworks) that chemically bind with CO2. Once the sorbent is saturated, it is heated, usually to 80–120°C (NEG8 Carbon employs 65°C), to release and recover the purified CO2, after which the sorbent is reused in another cycle.

Electrochemical DAC employs controlled electrochemical reactions to capture and release CO2. Air is passed over a reactive solvent that binds CO2. Electrical energy then drives the release of concentrated CO2. There are several different approaches in this category, including membrane electrodialysis (MED), bipolar-membrane electrodialysis (BPMED) and electro-swing adsorption (ESA). Another recent promising technology is pH-swing via proton-coupled electron transfer (PCET) however this method is still below a TRL level of 2-3 and is omitted from consideration here.

Energy Consumption of DAC

Role and Impact of Waste Heat

Solid sorbent DAC is uniquely suited to harness waste heat sources, such as heat from industrial plants, to provide the regeneration/heating step. This can lower energy costs by about 70% compared to sourcing heat from dedicated boilers or electric heaters.

Solid DAC requires low-grade heat (65−120°C), a form of thermal energy that is often rejected as waste from industrial processes. By siting a DAC plant adjacent to a source of industrial waste heat, the DAC system can obtain the necessary thermal energy at a near-zero cost and carbon footprint.

Electrochemical DAC is inherently all-electric, meaning it does not directly benefit from thermal waste heat. Its primary path to low energy use is through direct integration with low-cost renewable electricity.

The energy consumption in electrochemical DAC systems depends on the electrochemical approach taken. Which approach is chosen depends on which is most suitable, for example, where waste heat is available, solid sorbent DAC would make the most sense, likewise in freezing climates where added heat is needed. Electrochemical DAC would suit a site with readily accessible renewable energy. A comparative overview of both technologies is provided below.

Comparison Summary between Solid State DAC and Electrochemical DAC

| Solid-Sorbent DAC | Electrochemical DAC | |

| Energy Consumption | 1,400−3,000 kWh/tCO₂; Waste heat use can lower that to 400kWh. |

Varies by approach and maturity. BPMED: ~700–1,100+ kWh/tCO₂ (MIT) Membrane Electrodialysis: <800–1,500 kWh/tCO₂ Mission Zero: 800 kWh/t CO₂ Dual-cell electrochemical: RePair: 600kWh/t CO₂ ESA: Verdox: 420 kWh/t CO2 |

| Typical Heat/Electricity Source | Renewable/low-carbon electricity plus low-grade waste heat (<200°C). | Electricity only – renewable energy needed. |

| Regeneration Temperature | 65–120°C | Near ambient; process heat not needed. |

| Costs | Wide range: Currently ~$400–$1000/ tCO₂ for FOAK; Target <$100/ tCO₂ by ~2030. |

Varies. Electrolysis: $470–$1297/ tCO₂ Mission Zero target: <$300/ tCO₂ by 2026 (Medium). RePair target at scale: $70 Verdox (ESA) target: <€100/tCO2 |

| TRL (technology readiness) | Higher: TRL 7–8 at system level (Climeworks). Multiple pilot plants at TRL ~6-7 (Sirona, Skytree, CarbonCapture Inc) |

Lower overall. Some pilots/demos (Mission Zero, RepAir); generally TRL ~4–6; Mission Zero at ~6-7 |

| Scale-Up Outlook | Modular units already deployed; supply-chain maturity still developing (sorbent manufacture, large fans, vacuum systems). | Strong modularity and all-electric operation; large-scale proof and manufacturability of cells/stacks are the next tests. |

| Operational Complexity | Sorbent lifespan is a consideration: sorbents are generally stable and can be reused. Lower temperature regeneration in oxygen lean environments is advantageous.

Solid sorbent DAC typically works best in dry climates although humid conditions can improve CO₂ uptake. |

Cost of chemicals and replacement. The solvent can be reused (Mission Zero). Electrolytes and mediators (e.g., phenazines, quinones) are recyclable for thousands of cycles.

High cost of membranes. Typically, $750/m² (BPM) and $75/m² (ionic exchange membranes) which is a capital cost issue. Water is internally recycled though evaporative losses can arise. Toxicity effects may arise •The preferred mediators are non-toxic, earth-abundant compounds like quinones, phenazines, or polyoxometalates. •No major corrosion or leakage hazards are reported beyond standard electrolyte handling. Temperature Humidity and oxygen presence can hinder operation. |

| Examples | Climeworks, Skytree, CarbonCapture Inc., Sirona Technologies | Mission Zero (membrane electrodialysis), RepAir (dual-cell electrochemical), Verdox (ESA), |

Remarks

At this time, we believe the future of the burgeoning field of Direct Air Capture is very bright. The broad range of modular technologies summarised briefly in this short review, each with their individual pros and cons and applicability largely dependent on local energy resources and environmental conditions, demonstrate the significant activity taking place in this field in just the last five years. While technical challenges still exist, we feel these are not, and should not, be insurmountable.

One of the major issues however which remains is the need at individual national government level and in the broader context of cooperative international bodies to clearly develop policy directives regarding the deployment of DAC as a key tool to battle climate change.

Financial supports should also be established to enable fledgling DAC technologies of high potential to accelerate progress from pilot to direct carbon capture at scale. A key strategy in this respect could be the involvement of public-private partnerships to accelerate CDR rates via DAC in the coming decades.

Unlike technologies in the IT/AI sector, engineering projects involving large-scale atmospheric carbon capture are slow to evolve in the current environment and require major input from public bodies as well as private investment.

For more:

Appendix

Typical electricity use by electrochemical DAC

| Approach | Reported/derived electricity use (kWh/tCO₂) | Notes & sources |

| Electro-swing adsorption (ESA) | ~250–570 kWh/tCO₂ (lab modelling) to ~700–1,900 kWh/tCO₂ (including contactor/fans in some system studies) | MDPI American Chemical Society Publications Verdox (MIT): 420 kWh/t CO₂ |

| Bipolar-membrane electrodialysis (BPMED) | ~700–1,100+ kWh/tCO₂ (cell-level minima to system-level) | MIT |

| Membrane Electrodialysis (MED) DAC | <800–1,500 kWh/tCO₂ | Mission Zero notes <800 kWh/tCO₂ (Carbon Credits) |

Two Journal Article Overviews of Electrochemical DAC Technologies

Sustainability analysis of electrochemical direct air capture technologies Grazia Leonzio and Nilay Shah

RSC Sustainability, 3, 4632 (2025); https://doi.org/10.1039/d5su00227c

Summary

Overview

The paper compares four electrochemical DAC (eDAC) systems:

- Bipolar Membrane Electrodialysis (BPMED)

- Electrolysis-based DAC

- Proton-Coupled Electron Transfer (PCET)

- Electro-Swing Adsorption (ESA)

These systems are “fully electrified,” operating at ambient temperature and pressure, and powered by renewables (solar, wind, or nuclear).

Cost Summary

| System | Cost Range (USD/tCO₂) | Notes |

| Electrolysis | $470–$1297 (US/EU, depending on energy source) | Highest cost due to high energy use |

| BPMED | $417–$955 | Cost affected by membrane expense |

| ESA | $88–$130 | Lower due to reversible redox chemistry |

| PCET | $44–$84 (best case) | Lowest cost; scalable and renewable-friendly |

- Earlier BPMED model by Sabatino et al. estimated $773/tCO₂ and noted membrane price as the main limiting factor; cheaper membranes could reduce this to below $250/tCO₂

- Long-term projections suggest $100–600/tCO₂ by 2050 depending on material advances and electricity price

- Optimal operation projected 2040–2050, when electricity prices decline

Energy Use

- PCET: ~0.49 GJ/tCO₂ (≈136 kWh/tCO₂) — highly efficient

- ESA: ~90–113 kJ/molCO₂ → ≈ 2–2.5 GJ/tCO₂

- BPMED: 154–236 kJ/molCO₂ → ≈ 3.5–5.4 GJ/tCO₂

- Electrolysis: 164–374 kJ/molCO₂ → ≈ 3.7–8.6 GJ/tCO₂

Temperature and Climate Suitability

- eDAC operates at ambient conditions, so temperature extremes are less limiting than thermal DAC.

Water Use and Replacement

- The paper does not report major water loss from evaporation.

- Water is internally cycled during electrolysis or BPMED (via bipolar membrane dissociation), meaning replacement demand is low.

- Future LCAs suggest water and land use should be tracked during scale-up

Corrosivity and Toxicity

- Some redox mediators and catalysts (e.g., silver, cobalt) are potentially toxic or scarce; paper recommends avoiding such materials

- The preferred mediators are non-toxic, earth-abundant compounds like quinones, phenazines, or polyoxometalates

- No major corrosion or leakage hazards are reported beyond standard electrolyte handling.

Membrane and Chemical Costs

- Ion-exchange membranes are currently the main cost driver in BPMED and electrolysis systems

- Membrane improvements (better K⁺ selectivity and durability) could halve total costs.

- Electrolytes and mediators (e.g., phenazines, quinones) are recyclable for thousands of cycles—some systems report 7000+ stable cycles with 90% Faradaic efficiency

Key Takeaways

- PCET is the most economically and environmentally favourable eDAC process (as low as $44/tCO₂).

- BPMED and electrolysis remain costly due to membrane and energy demands.

- Systems operate efficiently at ambient conditions, without heat or pressure, but durability and membrane lifespan are major research areas.

- Water losses are minimal, but humidity management is relevant for reliability.

- Use of non-toxic, recyclable materials is essential for sustainability and scalability.

Advancements and Challenges in Direct Air Capture Technologies: Energy Intensity, Novel Methods, Economics, and Location Strategies

Janusz Kotowicz, Kamil Niesporek and Oliwia Baszczenska

Energies, 18, 496 (2025); https://doi.org/10.3390/en18030496

Summary

- Process Description

- Electrochemical DAC captures CO₂ using pH-swing or redox reactions instead of thermal regeneration.

- CO₂ is absorbed in an alkaline electrolyte and released in an acidic chamber through proton-induced pH changes.

- Hydrogen co-generation is sometimes integrated to lower operating costs.

- Some systems use bipolar membrane electrodialysis (BPMED) to create local pH gradients via water dissociation.

- Others use redox-active compounds (e.g. quinones, phenazines) on electrodes—called Electro-Swing Adsorption (ESA).

- Energy Use & Cost

| Process Type | Energy Use | Equivalent (kWh /t CO₂) | Indicative Cost |

| Electrolysis (ideal) | 162 kJ/mol | ~4,000 kWh/t | ~ $250/t CO₂ |

| Electrodialysis (ideal) | 154 kJ/mol | ~3,850 kWh/t | ~ $250/t CO₂ |

| Bipolar membrane ED (BPM-CEM) | 17–24 MJ/kg CO₂ | ~4,700–6,700 kWh/t | Potential <$250/t CO₂ |

| ESA (Verdox-type) | 35–65 kJ/mol | ~1,000–1,800 kWh/t | Competitive with solid sorbent DAC |

Most of the total energy (>96%) is consumed by the electrochemical cells themselves.

- Cost Estimates

- General DAC (all approaches) cost estimates range $100–1,000 per t CO₂.

- Electrochemical systems are not yet commercial, but BPMED and ESA variants could fall below $250/t CO₂ if membrane and redox material prices drop.

- Membranes & Chemical Reuse

- Ion-exchange membranes (BPM, CEM, AEM) are major cost drivers; specific prices are not quoted, but the paper stresses the need to reduce voltage drop and selectivity losses to cut total system costs.

- Sorbent regeneration efficiency can reach ~59% per cycle, with CO₂ purity > 95%.

- Electrodes and catalysts are stable for > 100 hours without degradation.

- Chemical reuse is high—alkaline solvents (NaOH/KOH) and H₂ recycling enable partial loop closure.

- Toxicity & Corrosivity

- No acute toxicity issues are reported for eDAC electrolytes, but oxygen sensitivity is a recurring limitation.

- Some redox-active compounds (e.g. thiolates, quinones) are reactive to oxygen and degrade over time.

- The review contrasts this with liquid DAC, where thermal degradation, oxidation, and toxicity/corrosivity remain major issues.

- Temperature & Climate Suitability

- Electrochemical methods are sensitive to humidity.

- Membrane humidity and oxygen presence can hinder operation in hot or moist climates.

- Solid sorbent DAC, by comparison, performs better in stable, warm, dry climates and is less suited to cold, humid regions, where capture costs can rise ≈ 40%.

- Water Usage

- The report does not note significant water losses from eDAC systems.

BPMED relies on internal water dissociation, not bulk evaporation, so water replacement requirements are minimal compared with liquid-solvent DACs.

- Key Comparison with Solid Sorbent DAC

| Criterion | Electrochemical DAC | Solid Sorbent DAC |

| Energy Type | Electrical (no heat required) | Thermal (low-grade heat ~100 °C) |

| Energy Use | ~1,000–6,000 kWh/t CO₂ | ~1,500–3,000 kWh/t CO₂ |

| Operating Temp. | Ambient; sensitive to humidity | 80–120 °C regeneration |

| Chemicals | Reusable electrolytes or redox materials | Amine-functionalised solids |

| O₂ Sensitivity | High (limits durability) | Moderate (amine oxidation) |

| Toxicity | Generally low; some redox agents reactive | Moderate (amine degradation products) |

| Water Needs | Minimal | Moderate (humidity affects adsorption) |

| Cost Range | <$250 potentially (future) | ~$400–600 current average |

| Scalability (TRL) | Lab-to-pilot (TRL 3-5) | Commercial pilot (TRL 7-8) |

| Climate Suitability | Best in dry, controlled settings | Best in warm, dry regions |

- Overall Notes

- Electrochemical DAC is promising but immature, mainly limited by:

- Membrane durability and oxygen corrosion.

- High capital cost for electrolysers and membranes.

- Solid sorbent DAC is more developed but needs stable heat sources.

- eDAC could complement renewable-based DAC as part of a fully electrified CO₂-removal system, especially where waste electricity or hydrogen by-products are available.

References

- https://www.missionzero.tech/lab-notes/electrochemical-direct-air-capture

- https://www.sciencedirect.com/science/article/pii/S2451929423006162

- https://www.energy.gov/science/doe-explainsdirect-air-capture

- https://blog.alliedoffsets.com/dac-processes-types-of-dac-and-current-state-of-dac

- https://ceclab.seas.upenn.edu/page/direct-air-capture

- https://www.sciencedirect.com/science/article/pii/S2212982023001981

- https://www.sciencedirect.com/science/article/pii/S2772656823000180

- https://www.nature.com/articles/s41467-023-35866-w

- http://large.stanford.edu/courses/2024/ph240/cranmer1/

- https://www.wri.org/insights/direct-air-capture-resource-considerations-and-costs-carbon-removal

- https://cleanenergyreview.io/p/carbon-capture-is-an-energy-problem

- https://www.statista.com/statistics/1416958/direct-air-capture-energy-requirements/

- https://pubs.acs.org/doi/10.1021/acs.energyfuels.4c02202

- https://www.sciencedirect.com/science/article/pii/S2772656825000909

- https://www.codema.ie/wp-content/uploads/2024/09/Recommendations_Paper_-_From_Data_Centres_to_DHC_-_Boosting_waste_heat_recovery_to_support_decarbonisation.pdf

- https://colloide.com/waste-heat-recovery-in-district-heating/

- https://www.sciencedirect.com/science/article/abs/pii/S1385894724008969

- https://www.rechargenews.com/energy-transition/the-amount-of-energy-required-by-direct-air-carbon-capture-proves-it-is-an-exercise-in-futility/2-1-1067588

- Geospatial techno-economic and environmental … — ScienceDirect (solid sorbent electrified process)

https://www.sciencedirect.com/science/article/pii/S2949790624002374 ScienceDirect - “Direct Air capture (DAC) deployment: A review of the …” — ScienceDirect ScienceDirect

https://www.sciencedirect.com/science/article/pii/S0009250923009727 - “Technical, economic and lifecycle greenhouse gas …” — ScienceDirect ScienceDirect

https://www.sciencedirect.com/science/article/pii/S277265682500020X - “Model-Based Energy and Cost Analysis of Direct Air Capture …” — ACS Publications American Chemical Society Publications

https://pubs.acs.org/doi/10.1021/acssuschemeng.4c05769 - “Reviewing direct air capture startups and emerging …” — ScienceDirect ScienceDirect

https://www.sciencedirect.com/science/article/pii/S2666386424000110

(PDF version: https://www.cell.com/cell-reports-physical-science/pdf/S2666-3864%2824%2900011-0.pdf) Cell - “Mission Zero Technologies: Phase 1 report” — UK government / consortium report (PDF) UK

https://assets.publishing.service.gov.uk/media/6281f1e4e90e071f61322114/mission-zero-technologies-d4.8-project-phase-1-report.pdf - “Considering technology characteristics to project future …” — Joule / Cell (on DAC cost trajectories) Cell

https://www.cell.com/joule/fulltext/S2542-4351%2824%2900060-6 - “Direct Air Capture: Definition and Company Analysis” — U.S. Department of Energy report (PDF) The Department of Energy’s Energy.gov

https://www.energy.gov/sites/default/files/2025-01/Direct%20Air%20Capture%20Definition%20and%20Company%20Analysis%20Report.pdf - “The energy and cost dynamics of direct air carbon capture” — SpringLink / Springer SpringerLink

https://link.springer.com/article/10.1557/s43581-024-00091-5 - “Breaking Barriers in Carbon Dioxide Removal with Electrochemistry” — RMI RMI

https://rmi.org/wp-content/uploads/dlm_uploads/2024/09/rmi_breaking_barriers_cdr.pdf - “6 Things to Know About Direct Air Capture” — WRI World Resources Institute

https://www.wri.org/insights/direct-air-capture-resource-considerations-and-costs-carbon-removal - “Direct Air Capture Case Studies: Sorbent System” — NETL / U.S. DOE (PDF) doe.gov

https://www.netl.doe.gov/projects/files/DirectAirCaptureCaseStudiesSorbentSystem_070822.pdf - “The State of Direct Air Capture Technology and Industry” — Waterloo Climate Institute (PDF) University of Waterloo

https://uwaterloo.ca/climate-institute/sites/default/files/uploads/documents/dac-brief_final_may-2025_v2.pdf - “Sustainability analysis of electrochemical direct air capture …” — RSC (Royal Society of Chemistry) RSC Publishing

https://pubs.rsc.org/en/content/articlehtml/2025/su/d5su00227c - “Direct Air Capture: A key technology for net zero” — IEA (PDF) IEA Blob Storage

https://iea.blob.core.windows.net/assets/78633715-15c0-44e1-81df-41123c556d57/DirectAirCapture_Akeytechnologyfornetzero.pdf - IEAGHG

Interested in NEG8 Carbon’s CO2 capture technology?