What is CO2 Utilization?

Carbon dioxide utilization refers to using or repurposing CO2 that has been captured using Direct Air Capture or point source carbon capture. It is an alternative to sequestering the captured CO2.

By utilizing CO2 and repurposing it into products and processes, we can either lock away the CO2 forever, e.g. in concrete, or bring it into a circular usage cycle, as is the case with Sustainable Aviation Fuel.

Value of Carbon Utilization

Utilizing CO2 that has been captured can lower the costs of reducing emissions by turning waste into revenue-generating products.

We use approximately 230 million tonnes of carbon dioxide annually in a number of processes.

Traditionally, the CO2 is produced in synthesis gas plants such as ammonia/ hydrogen production, in breweries through the fermentation process, or through burning fossil fuels such as natural gas. So instead, we can capture CO2 in a more environmentally friendly way using DAC.

Where Utilization of CO2 can be Employed

The most promising areas of CO2 usage are:

eFuels

Combining hydrogen with CO2 can produce hydrocarbon fuels and replace fossil fuels for high energy applications e.g. shipping, heavy duty vehicles and aviation. However, for these fuels to be economically viable and carbon neutral, we need a cheap and environmentally safe source of hydrogen.

Grey hydrogen is produced with coal or lignite gasification and is a carbon-intensive processes.

Blue Hydrogen is produced via natural gas or coal gasification but the CO2 emitted is captured at the source using carbon capture and storage (CCS) technologies.

Green hydrogen is produced using electrolysis of water with electricity generated by renewable energy. It can only be considered truly green if the electricity used is from a carbon-neutral source.

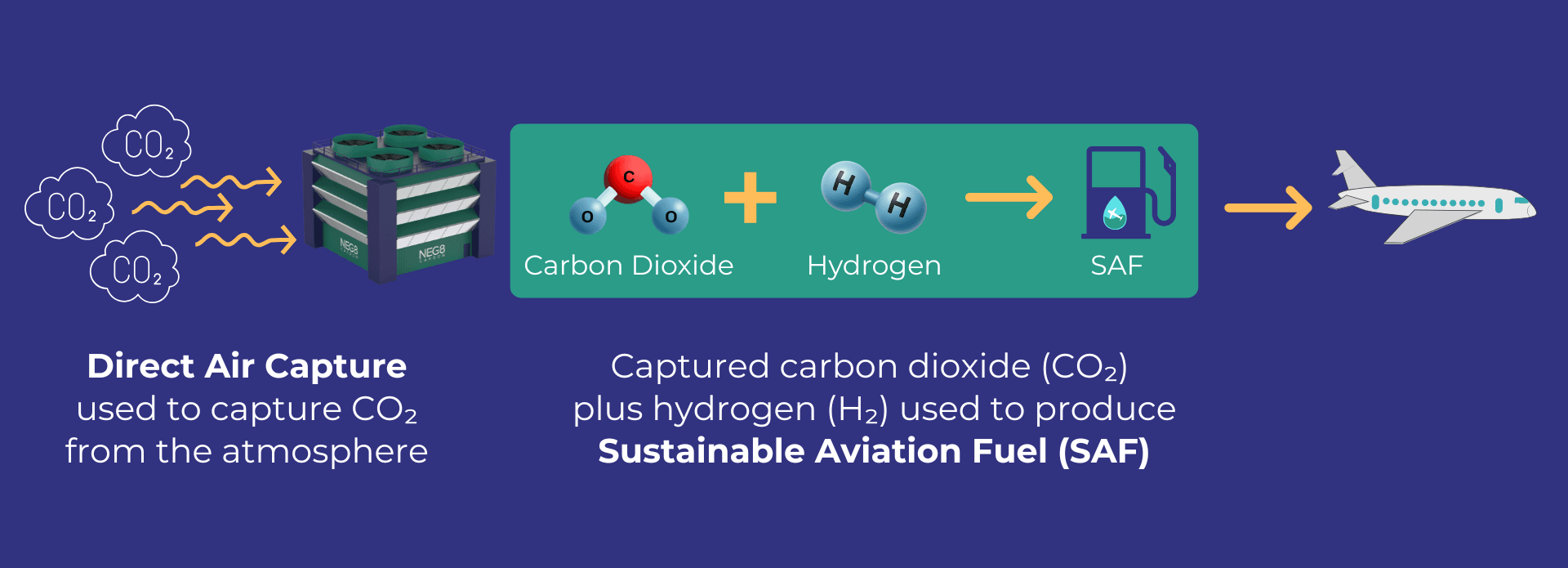

Sustainable Aviation Fuel (e-SAF)

Aviation is a major culprit of CO2 emissions and this industry is under intense pressure to reduce the fossil fuel component of its fuels. For example, the EU is mandating the increased use of SAF at airports (2% by 2025 and 70% by 2050). In this context, Sustainable Aviation Fuel offers a solution for the future of aviation as a greener and more viable industry.

The captured CO2 can be converted into synthetic fuel which can reduce aviation carbon emissions by up to 80%. SAF can be blended with conventional jet fuel, and since it’s chemically similar to jet fuel, it won’t require any engine modifications to introduce.

Sustainable Concrete and Construction Materials

Innovative techniques allow CO2 to be stored in low-carbon sustainable concrete and building materials, effectively sequestering carbon in long-lasting structures. The CO2 reacts with minerals to form stable carbonates, which can be used in construction materials like concrete. In so doing, this method reduces emissions from one of the largest polluting industries—construction.

Food and Beverage Industry

Food grade CO2 is widely used in the food and beverage industry, for example, for carbonation in soft drinks. It is also used for refrigeration and packaging processes to enhance product preservation. Dry ice is a wide-spread application of CO2. It is produced by converting liquid CO2 into its solid form by compressing and cooling it and then releasing it to create dry ice.

Chemical Manufacturing and Chemical Feedstock

Industries utilize CO2 as a raw material to synthesize important chemicals such as methanol, urea, and polycarbonates. What’s more, CO2 can be converted into valuable products such as plastics, resulting in less reliance on fossil fuel-derived materials. Taking it a step further, companies like Fortnum Recycling & Waste in Finland[1] have succeeded in making biodegradable plastic from captured CO2.

One of the largest consumers of CO2 for industrial processes is the fertilizer industry. Urea is a nitrogen-based fertilizer that is produced by reacting ammonia with carbon dioxide, and therefore, this industry could swap in captured CO2 to reduce the carbon footprint of fertilizer production.

Bio-based Utilisation (Algae and Plants) and in Greenhouses

Certain plants, algae, and microbes can absorb CO2 and use it to grow as plant growth and quality are enhanced by using CO2. This process can produce biofuels, biomass, food, or other bio-based materials. These organisms can be cultivated on non-arable land, which then bypasses the food vs fuel conflict.

There are some hurdles to overcome, though, as establishing large-scale facilities requires substantial investment. Also, environmental conditions can affect productivity, leading to inconsistent results.

Pharmaceuticals and Medical Use

CO2 finds various applications in medical fields, including cryotherapy, where it is used for its cooling properties.

CO2 as a New Material

Carbon nanotubes and graphene are some of the latest man-made materials which are currently used in specialised applications. The availability of large volumes of CO2 allows for the possibility of using carbon fibres for industrial wiring and the widespread replacement of steel and concrete by carbon composites.

For more:

Interested in carbon capture technology?

Sources used in this blog include:

www.iea.org

www.neonscience.org

https://www.weforum.org