Sustainable Aviation Fuel (SAF) for Greener Skies

By: Prof. Don MacElroy | Chairman of the Advisory Board at NEG8 Carbon

Globally, aviation was responsible for almost 950 million tonnes of CO₂ emissions in 2023 [International Energy Association], and with the world’s love for travel as strong as ever, the industry needs to step up and address the challenge of reducing this figure.

With increased pressure from all sides, aviation companies are now on a quest to leave the skies ‘greener’ and using sustainable aviation fuel (SAF) is an integral part of this endeavour.

What is Sustainable Aviation Fuel?

As the name suggests, sustainable aviation fuel is made using sustainable feedstock and processes. The SAF process uses renewable feedstock, such as waste cooking oils and municipal waste, and the resulting fuel has similar chemical properties to conventional jet fuel.

However, efuels made from green hydrogen and captured CO₂ are catching the attention of the aviation industry.

Sustainable aviation fuels are called ‘drop-in’ fuels as they can be blended with conventional jet fuel and used with existing aeroplane engines without any need for modifications. This is a huge plus as the aviation industry can reduce its carbon footprint without the need to redesign the plane engines or infrastructure.

Depending on the feedstock and production method used, SAF can achieve emissions reductions of up to 80%.

Why do we Need SAF?

Aviation accounts for roughly 2.5% of global CO₂ emissions, a figure that is predicted to rise unless there are solid interventions made. Unlike road transport, which can relatively easily transition to electric power, aircraft require energy-dense fuel to cover the vast distances they fly.

SAF offers a solution that can dramatically reduce the carbon footprint of flights while using existing engine technology. One compelling advantage is that SAF offers immediate emissions reductions and can be scaled up as technology improves and costs decrease.

How is Sustainable Aviation Fuel Made?

The production of SAF taps into various renewable resources. Broadly speaking, SAF can be derived from sustainable feedstocks such as used cooking oil, agricultural and municipal waste, or green hydrogen and carbon dioxide captured directly from the air. These materials are refined to create a fuel that works in aeroplane engines in the same way as conventional jet fuel.

Hydrocarbon fuels are of particular interest.

Efuels/ Power-to-Liquid (PtL) Fuels: SAF made from Captured CO₂

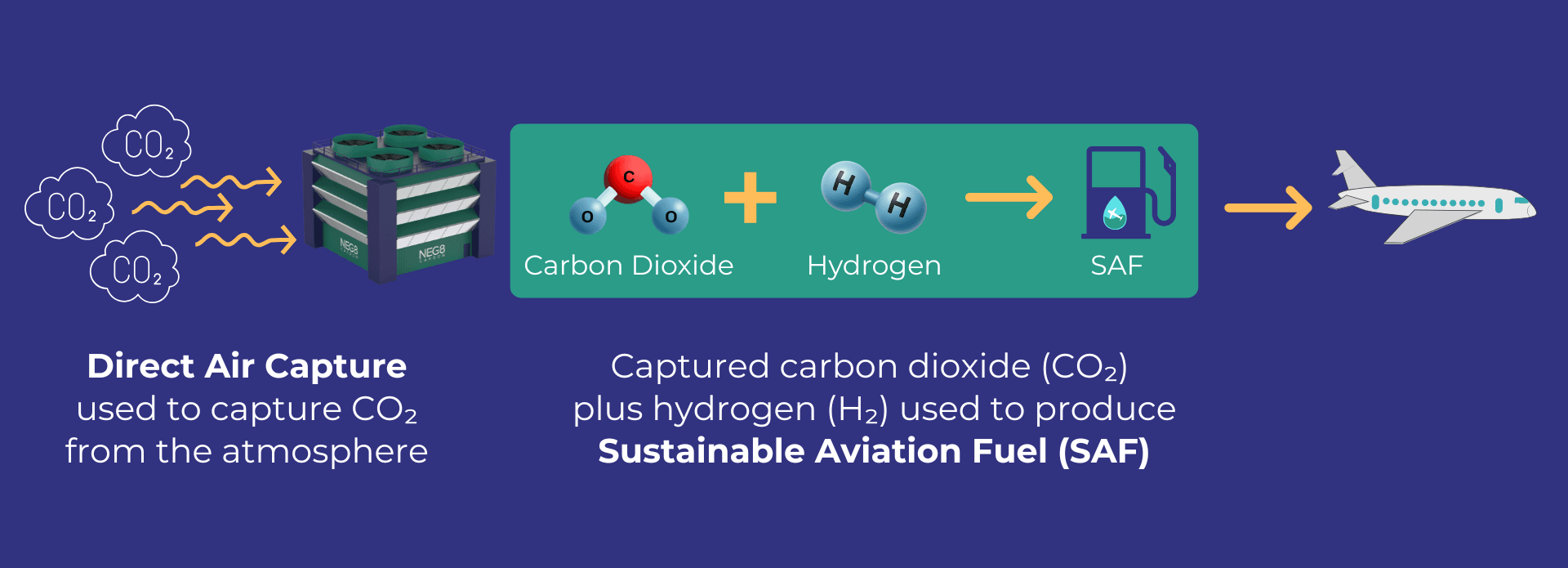

eFuel (electrofuel) is made using renewable electricity to create green hydrogen, which is then combined with captured CO₂ to form a liquid fuel. It is imperative that renewable energy is used in the process, as the electrolysis used for green hydrogen production is highly energy intensive.

Direct Air Capture’s Role in Sustainable Aviation Fuel Production

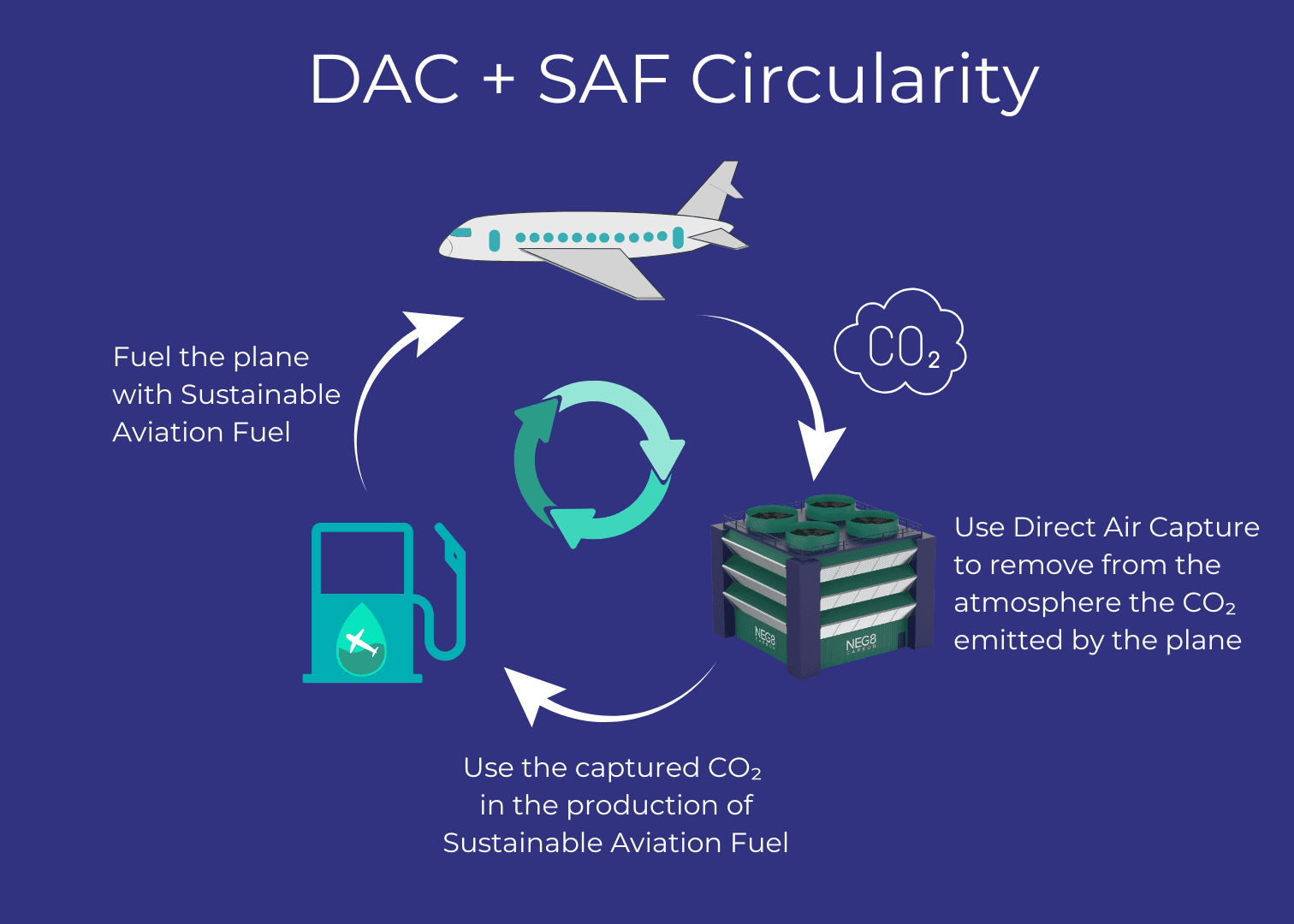

DAC can work together with SAF in an enclosed system. So simply put, SAF requires CO₂ to make power-to-liquid fuels, and captured CO₂ needs to be utilized (if it’s not sequestered). It’s a perfect partnership that works towards a more sustainable aviation industry.

It is a circular process, removing CO₂ emissions from the air produced by aviation and then utilizing the captured carbon dioxide for eFuel – while also reducing the amount of CO₂ emitted. (See: What is CO₂ Utilization?)

Using Low-Grade Waste Heat from Hydrogen Electrolysers

Electrolysers generate a significant amount of low-grade waste heat during hydrogen production. Instead of letting this energy go unused, DAC systems can harness it to support their CO₂ capture processes. This co-location reduces the operating costs of DAC while making better use of the total energy input into the site. The captured CO₂ and green H₂ can then be synthesised into SAF via Fischer–Tropsch or other suitable processes, all on a single integrated site, which cuts down on emissions and transport costs. (See: Direct Air Capture Use Cases)

What is the difference between SAF and e-SAF?

While SAF includes biofuels derived from, for example, biomass, vegetable oils and waste fats, e-SAF is a specific type of SAF made using green energy to produce hydrogen and captured CO₂ which are synthesised into aviation fuel.

Other Types of Sustainable Aviation Fuel

HEFA (Hydrotreated Esters and Fatty Acids)/ Biofuels

HEFA is a process used to produce sustainable aviation fuel by refining vegetable oils, animal fats, or other renewable feedstocks into high-quality jet fuel

Alcohol to Jet

The alcohol-to-jet (ATJ) process converts alcohols like ethanol or butanol into jet fuel through dehydration, oligomerisation, and hydrogenation, producing a sustainable alternative to conventional aviation fuels.

SAF vs Jet Fuel

Sustainable aviation fuel performs virtually identically to conventional jet fuel, it meets the same quality standards and is compatible with existing aircraft engines.

However, when contrasted with traditional jet fuel, SAF provides notable environmental advantages. Conventional jet fuel is a fossil-based product that releases substantial amounts of CO₂, whereas SAF is specifically designed to have a lower carbon footprint across its entire lifecycle.

The real impact of SAF lies in this lifecycle; while burning SAF still produces emissions similar to those from fossil fuels, it primarily uses carbon that is already part of the current carbon cycle through various feedstocks or captured using technology like Direct Air Capture.

Moreover, SAF often leads to fewer particulates and sulphur emissions, thereby improving air quality around airports. Another advantage of SAF is that it has shown higher density in flights, which allows aeroplanes to fly further on less fuel.

Importantly, SAF matches conventional jet fuel in terms of key performance and safety specs, ensuring reliable operation under all conditions.

Regulations Driving SAF Implementation

The push for SAF is a global undertaking. Both the European Union and the United States have recognised the potential of this alternative fuel and are drawing up regulations to accelerate its adoption.

Since these regulations are not voluntary, the demand for SAF will increase as the regulations grow tighter. And by mandating SAF usage, they encourage the development of new SAF technology.

To start with, the International Air Transport Association (IATA) has put its hand up and committed to achieving net-zero carbon emissions by 2050, with SAF forming a key role in this initiative.

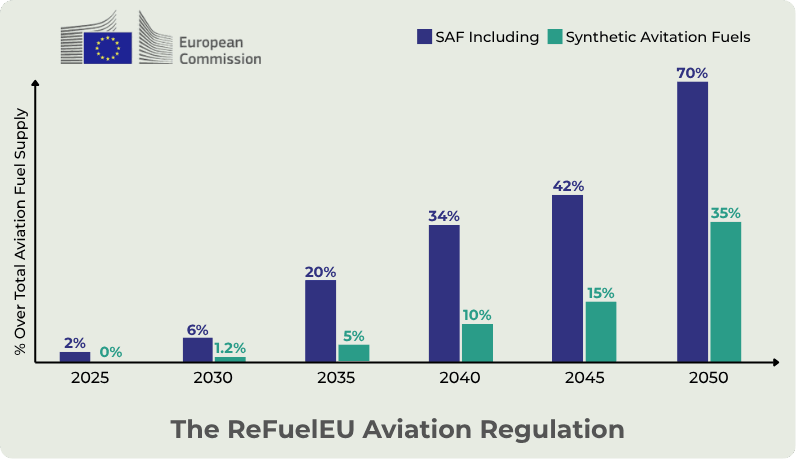

SAF Regulations: EU

In the EU, the ReFuelEU Aviation initiative aims to mandate a gradual increase in SAF blending for flights originating in the EU, starting with a modest 2% in 2025 and ramping up to 6% by 2030, 20% by 2035, and up to 70% by 2050. SAF covers synthetic fuels, biofuels and recycled carbon fuels based on the sustainability criteria of set out in the Renewable Energy Directive (RED) (Directive (EU) 2018/2001). This initiative forms part of the EU’s Fit for 55 package which has a greenhouse gas (GHG) emissions reduction target of 55% versus 1990 by 2030.

SAF Regulations: US

Meanwhile, the USA has set ambitious goals through the SAF Grand Challenge, aiming to produce at least 3 billion gallons (11.3 billion litres) of SAF annually by 2030 and 35 billion gallons by 2050 for all US domestic needs.

Furthermore, the USA has introduced initiatives like the Sustainable Skies Act (introduced in May 2021), which provides tax credits and incentives for SAF production and usage. Credits up to $2/gallon for GHG-saving SAF, and other state-based tax credit systems.

SAF Regulations: UK

Similarly, the UK government, for instance, has set a SAF target that mandates at least 2% of aviation fuel must be from sustainable materials by 2025, 10% by 2030 and 22% by 2040.

Sustainable Aviation Fuel Costs

There’s no getting away from it – SAF is currently more expensive than conventional jet fuel due to limited production capacity and high feedstock prices. Today the price can be two to four times higher, depending on the production method and feedstock used and feedstock availability.

Recently (https://roberthoglund.medium.com/) the costs have been compared between:

Continued utilization of fossil-based jet fuel combined with Direct Air Carbon Capture and Storage (BAU-DACSS)

vs

Direct replacement by eFuels (Green H2 + CO2 from Direct Air Capture (DAC)).

Based on estimated costs for 2050, the conclusion drawn from this study is that efuels will cost up to 50% more than the alternative by that time.

However, parity is predicted for both scenarios if fossil fuel costs significantly increase and simultaneously electricity costs are very low.

It is important to note that these margins are based on economic considerations alone and the social and health impacts of continued fossil fuel use through emissions and the environmental impact of fuel exploration, production and refining requires careful study.

Many argue that the environmental benefits of SAF justify the higher price tag.

Example: CO₂ for Net-Zero SAF Production in Ireland

Production of jet fuel (taken as kerosene) from CO2 and H2 as reactants results in: 0.32 tonnes of fuel per tonne of CO₂

The daily consumption of jet fuel for Ireland in 2023 [1] was: 3010 tonnes per day (23,340 barrels per day)

This implies approximately 1.1 million tonnes of jet fuel per year.

Therefore, the CO2 requirement sourced from Direct Air Capture to achieve net-zero aviation emissions is: 1.1/0.32 = 3.44 million tonnes CO₂ per year

This is the share of aviation within/to/from Ireland to the hard-to-abate emissions in the atmosphere.

Final Thoughts

While challenges remain, particularly in terms of cost and scale, the potential benefits of SAF make it central to the aviation industry’s sustainability strategy. As regulations evolve and production ramps up, we can expect to see SAF playing an increasingly important role in our journey towards cleaner skies.

For more:

- Direct Air Capture Cost Compared to Cost of Inaction on Climate Change

- Hard to Abate Industries and the Decarbonization Challenge

- Lift Off for NEG8 Carbon in Sustainable Aviation Fuel

- Is DAC Viable?